Spreadable Cheese Analogue

Heat palm kernel fat until it is melted Mix all dry ingredients and add to water Mix the dry blend into water Add the melted fat to the mix Heat on low speed up to temperature of 80C and hold for 5 minutes Place the mix into moulds and cool in a fridge. Bahan-bahan yang digunakan pada Spreadable Cheese Analogue adalah Edam Cheese Cheedar Cheese Isolat Soy Protein Tepung Maizena Minyak Nabati Air Garam Dapur Emulsifier Trisodium Sitrat Cheese Cheese optimationDisodium Sulfat Distilled Monoglyceride Asam asetat HCl 6N.

The Absolute Worst Pumpkin Related Food Crimes Pumpkin Recipes Pumpkin Scones Food

Our unique selection of extracts provide a wide range of textures from the most soft and creamy spreadable cream cheese.

Spreadable cheese analogue. Stretching melting spreadability and stability over shelf life. Effect of the type of fat on rheology functional properties and sensory acceptance of spreadable cheese analogue. Processing of the spreadable processed cheese analogues.

Making cheese analogue. 1132-22005 for processed cheese with vegetable oils and. As a consequence these analogues showed lower melting lower spreadability higher hardness and higher values for the elastic and viscous moduli than cheese made with butter oil.

Abstract Milk protein concentrate in Low-Fat Spreadable processed cheese analogue replaced and substituted with synergized filler branded as Gervizol which containing soy proteins soy fibers maltodextrine and modified starch. This video details the different steps in the production of cheese analogueVideo made by Niclas Frederiksen. 212 Mould ripened cheese is a ripened cheese in which the ripening has been accomplished primarily by the development of characteristic mould growth throughout the interior andor on the surface of the cheese.

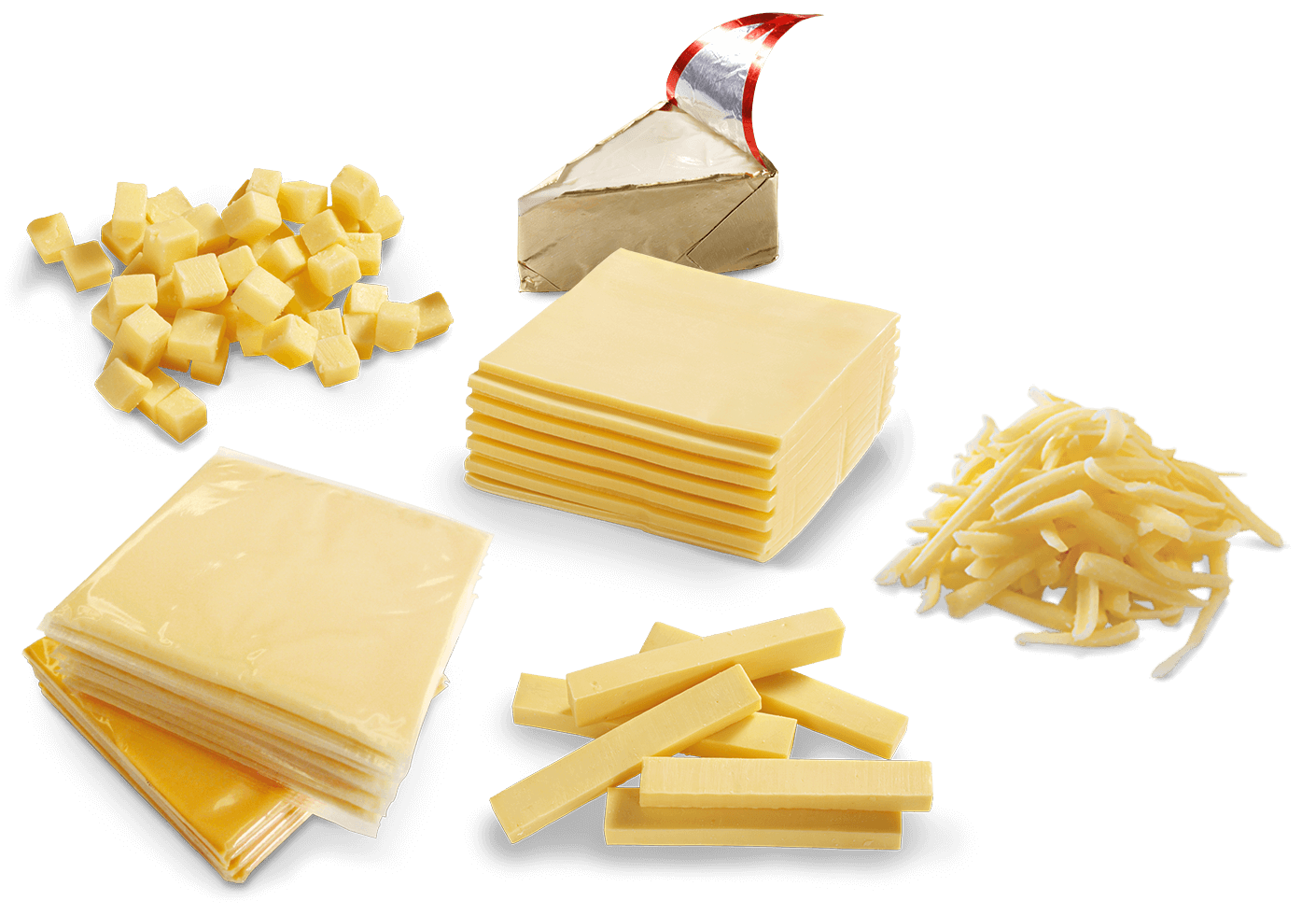

Cooker Cooler Mixer. It protects processed cheese from crystallization and maintains natural appearance over time. The Spreadable Cheese Analogue are Edam Cheese Cheddar Cheese Soy Protein Isolate cornstarch Vegetable Oil Water Salt Emulsifier Trisodium Citrate Disodium Sulfate Distilled Monoglyceride Acetic Acid HCl 6N.

Processed cheese is the ideal product in the consumer market as it has a much longer shelf life than natural cheese and these product cover all the requirements concerning quality and hygiene. Glacier Ridge Farms Smoked Gouda Gourmet Spreadable Cheese 8oz One Cup 8 Ounce Pack of 1 44 out of 5 stars. The studied alga enhanced the cheese analog with the high levels of selenium zinc iron magnesium and potassium.

The full fat half fat and low fat spreadable processed cheese analogues were prepared under the guide lines recommended by the Egyptian Organization for Standardization and quality. Ceamlacta carrageenan Ceambloom carrageenan and Ceamtex alginate products improve the creaminess cohesiveness and elasticity of processed and analogue cheese. 213 Unripened cheese including fresh cheese is cheese which is ready for consumption shortly after manufacture.

Antioxidant activity in the cheese enhanced. It provides firm shape good taste and elasticity to the cheese with easy to shred and slice properties. Formulation for cheese analogues The major protein source in dairy-based Analogue Cheese Products ACPs is caseinate or rennet casein with the former being used mainly for spreadable products.

Processed cheese analogue cheese. Rennet casein is favored for semi-hard block products and especially for APC where it generally. Analogues made with partially hydrogenated soybean fat or soybean oil in substitution to butter oil presented lower fat globule size.

Corino is specially curated for blocked cheese spreadable processed cheese cheese for sandwich and burger and pizza and cheese analog. The type of cheese analogue which is widely made and used is spreadable cheese analogue because its manufacture is relatively easy and simple 3. They were formulated under the regulations appeared in the Egyptian Standers ES.

Production costs are kept low through complete ingredients usage while we help you to create an efficient line for your processed cheese needs. The coagulation process is an important stage which determines the texture and flavour of the cheese 4. Corino is used to provide improved ion exchange properties to block cheese.

In order to help the coagulation process rennet enzyme is added as the coagulant 5. The tools for produced the Spreadable Cheese Analogue are scales plastic containers spoons.

Processed Cheese Natec Network Success Generating Food Technology

Processed Cheese Natec Network Success Generating Food Technology

The Laughing Cow Laughing Cow Cow Cheese Cheese Brands

Texturizer Solutions For Cheese And Analogue Ceamsa

The Power Of Starch Creating Cheese Products With Superior Texture Asia Pacific Food Industry

Show Your Body Some Love With Zo Tea Oatly Milk Packaging Milk Brands

Processed Cheese Natec Network Success Generating Food Technology

Texturizer Solutions For Cheese And Analogue Ceamsa